AI in the Automobile Industry: Driving the Future Forward

Table of Contents

- I. Executive Summary — Why AI Is Rewriting the Automotive Industry

- II. The Core AI Technologies Powering Modern Vehicles

- III. AI in Manufacturing & Supply Chain

- IV. Autonomous Driving — What’s Real vs Hype

- V. AI for Customer Experience & After-Sales

- VI. Electric Vehicles (EVs) — Why AI Is the Power Behind the Battery

- VII. The Data Advantage — Why Automakers with Big Data Win

- VIII. Challenges, Risks & Ethical Considerations

- IX. Real-World Case Studies

- X. Framework: How Auto Companies Should Adopt AI (Product Manager POV)

- XI. The Future of AI in Automotive: 2025–2030 Predictions

I. Executive Summary — Why AI Is Rewriting the Automotive Industry

In less than a century, automobiles have undergone three revolutions.

The mechanical era gave us engines and horsepower.

The smart era added sensors, ECUs, GPS navigation, and infotainment.

But the AI era—the one unfolding right now—is rewriting what a “car” even means. For the first time, vehicles are becoming adaptive, intelligent, predictive systems rather than machines that merely respond to drivers.

Picture this:

A car that predicts a component failure weeks before it happens.

A factory line that adjusts itself in real time to avoid defects.

A dealership that knows what a customer wants before they walk in.

A supply chain that routes itself to avoid delays.

An in-car assistant that monitors fatigue, stress, or distraction to prevent accidents.

This isn’t future hype.

It’s happening right now—and it’s powered by AI.

Why AI Is No Longer Optional for Automotive Companies

For decades, automakers competed on horsepower, build quality, and design. In 2025, those are table stakes. The new competitive frontier is:

Predictive intelligence → cars that learn & personalize

Autonomous functions → from Level 1 to Level 3/4 autonomy

AI-driven manufacturing → fewer defects, faster cycles

AI in safety → monitoring driver intent, road conditions, collision probability

AI in EV optimization → extending battery life & range

AI in after-sales → predictive maintenance & service automation

AI in sales & retail → digital showrooms, personalization, generative marketing

Simply put:

AI is the difference between a surviving automaker and a dominant one.

Those who fail to adopt AI risk falling behind not in years—but in months.

2025 Market Reality: The Auto-AI Industry Is Exploding

According to Statista, the global automotive AI market will reach $74–80 billion by 2030, growing at a staggering CAGR of over 22%.

McKinsey reports that AI-centered vehicle software could unlock $125–150 billion in annual value by 2030.

In 2025 alone:

Over 78% of new vehicles shipped with AI-enabled advanced driver-assistance systems (ADAS).

90% of OEMs increased AI investments across manufacturing, R&D, and customer experience.

EV companies like Tesla, BYD, Rivian, and NIO now treat themselves not as automakers—but as software & AI companies on wheels.

The market isn’t expanding—it’s transforming.

Key Thesis: AI Goes Far Beyond Autonomous Driving

Most of the public conversation focuses on self-driving cars, but autonomy is only one chapter of the automotive AI story.

The full transformation spans:

Manufacturing → robotic automation, vision-based quality checks

Design & engineering → generative AI for aerodynamics & simulations

Supply chain → AI forecasting, route optimization, digital twins

In-car experience → natural language interfaces, sentiment recognition

Safety → predictive risk modeling, distraction detection

Retail → personalized recommendations, virtual showrooms

After-sales → predictive service alerts, remote diagnostics

Insight:

AI is no longer a feature; it is the backbone of the automotive value chain.

From concept sketches → to production → to ownership → to resale, AI plays a role at every stage.

If the 20th century belonged to companies that mastered engines, the next decade belongs to companies that master algorithms, intelligence, and data.

Cars are becoming software-defined products, and AI is the operating system driving the transformation.

This article will break down how AI is reshaping each layer of the automotive world—and what it means for the future of mobility, safety, and industry competition.

II. The Core AI Technologies Powering Modern Vehicles

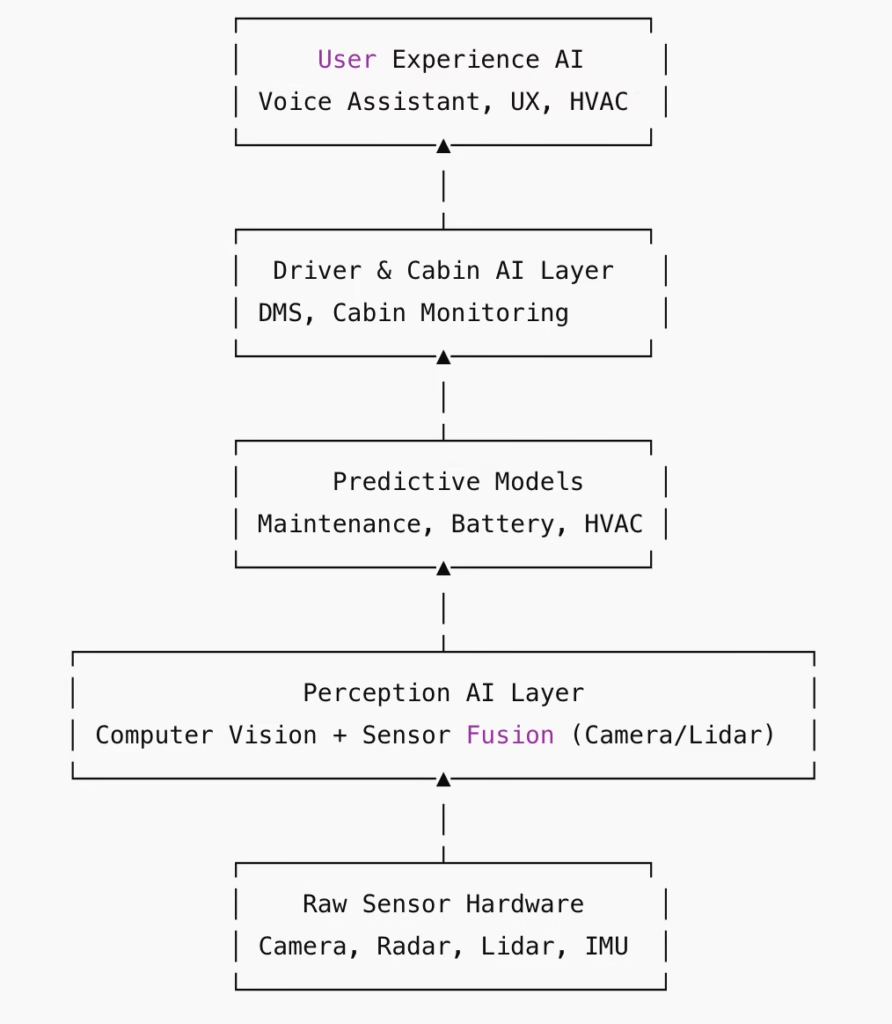

AI is not a single technology—it is a stack of intelligence layers working together to make modern vehicles safer, smarter, and more responsive. Below is a practical, engineering-friendly breakdown of the four foundational AI systems inside today’s cars.

1. Computer Vision — The Eyes of the Vehicle

Modern vehicles rely heavily on AI-powered vision systems to interpret the environment. Using deep learning models like CNNs and transformers, cars can now perceive the world with remarkable accuracy.

Key Capabilities

Lane detection → Identifies lane boundaries even in rain, snow, or faded paint.

Pedestrian detection → Recognizes walking patterns, predicting movement direction.

Traffic sign recognition → Interprets speed limits, stop signs, warnings, and lane restrictions.

Vehicle detection → Identifies nearby cars, motorcycles, cyclists.

Why Pixel-Level Semantic Segmentation Matters

Instead of labeling whole objects, segmentation labels each pixel.

Example:

Road = blue

Pedestrian = yellow

Vehicle = red

Sidewalk = gray

Sky = white

This creates a highly accurate scene understanding, essential for lane-keeping, emergency braking, and collision avoidance.

2. Sensor Fusion — Combining the Vehicle’s Senses

No single sensor is perfect. Cameras see color, Lidar measures depth, Radar works in rain/fog.

Sensor Fusion = Lidar + Radar + Cameras + Ultrasonic → One unified, real-time perception model.

How Companies Differ

| Company | Approach | Strengths | Weaknesses |

|---|---|---|---|

| Tesla | Vision-only (no Lidar) | Low cost, good in daylight | Struggles in fog/snow |

| Waymo | Lidar + Radar + Vision | Extremely accurate 3D maps, best for autonomy | Expensive sensor stack |

| Traditional OEMs | Hybrid approach | Balanced performance & cost | Slower innovation cycles |

Fusion algorithms (like Kalman filters, neural fusion, and Bayesian inference) ensure the car “trusts” the right sensor at the right time.

3. Predictive Maintenance Models — Cars That Fix Problems Before They Happen

AI allows vehicles to shift from reactive maintenance (fix after failure) to predictive maintenance (fix before failure).

How It Works

Sensors monitor:

Vibration

Temperature

Oil levels

Battery health

Motor performance

Brake pressure

AI models detect anomalies and forecast component failure.

Real Examples

Predicting EV battery degradation months in advance

Detecting early signs of brake pad wear

Identifying faulty fuel injectors from sound patterns

Transmission overheating alerts before breakdown

Result: Higher safety, lower maintenance cost, fewer roadside emergencies.

4. AI for In-Car Intelligence — The Brain Inside the Cabin

Modern vehicles use onboard AI not just for safety, but for comfort, personalization, and monitoring.

Key Systems

Voice Assistants

Natural language control (similar to ChatGPT)

Voice-based navigation, music, climate control

Hands-free safety features

Cabin Monitoring

Detects child presence

Monitors seatbelt use

Detects intrusion/theft

Adaptive HVAC

AI adjusts AC/heating based on:

Number of passengers

Sunlight exposure

Temperature patterns

Energy efficiency in EVs

Driver Monitoring Systems (DMS)

Eye tracking → drowsiness detection

Gaze tracking → distraction alerts

Emotion recognition → stress monitoring

Posture analysis → fatigue prediction

These systems significantly reduce human error, which contributes to 94% of road accidents (NHTSA).

Diagram: AI Tech Stack Inside a Modern Car

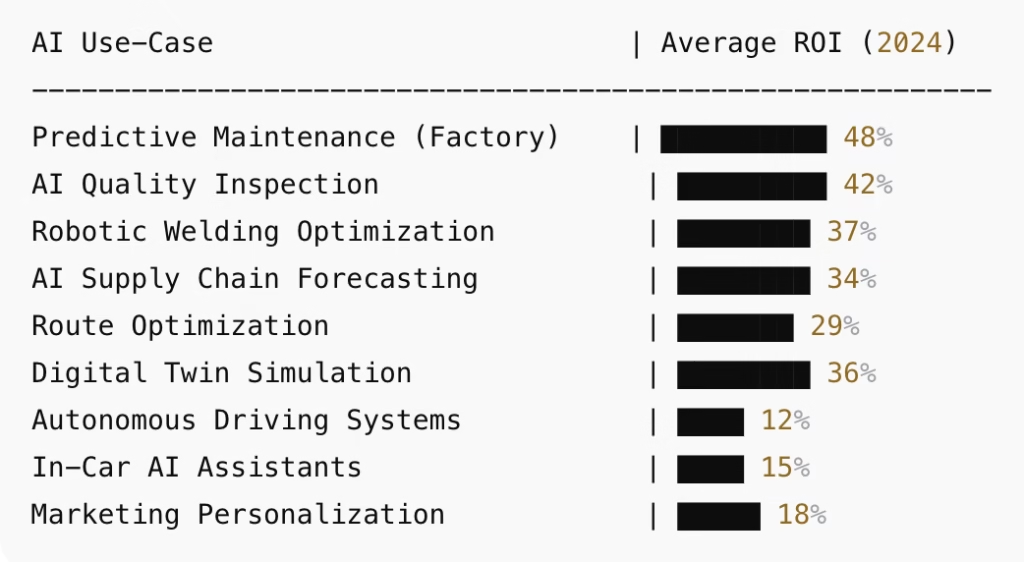

III. AI in Manufacturing & Supply Chain (The Hidden Engine of Automotive ROI)

When people think of AI in automobiles, they imagine self-driving cars.

But ask any automaker where AI delivers the highest profitability, and the answer is consistent:

Manufacturing + Supply Chain = Highest ROI in the automotive industry.

AI quietly powers the factories, logistics networks, and predictive systems that keep automakers competitive, efficient, and resilient. This is where billions are saved — long before a car ever touches the road.

A. AI in Manufacturing — Precision, Speed & Zero-Defect Goals

Modern car factories are no longer mechanical assembly lines — they’re intelligent ecosystems where robotics, sensors, and AI coordinate in real time. AI dramatically improves the accuracy, speed, and consistency of production while reducing human error.

1. Robotics + AI for Precision Welding

Automotive welding must be:

millimeter-accurate

high-strength

vibration-resistant

consistent across thousands of units

AI-enhanced welding robots use:

real-time heat monitoring

trajectory prediction

adaptive force control

Result:

Increased throughput

Increased throughputOEMs like Toyota, BMW, and Ford have reported up to 18–25% efficiency gains from AI-powered robotic welding systems.

2. Vision-Based Quality Assurance

Before AI, quality checks relied heavily on human inspectors.

Today, computer vision achieves accuracies humans can’t match.

AI systems inspect:

paint quality

body alignment

microcracks

fastener placements

surface defects

They detect flaws at pixel-level precision, identifying defects invisible to the human eye.

Mercedes-Benz uses AI vision to inspect 100% of vehicles before rollout.

Error detection improved by over 90%.

3. Real-Time Defect Detection

Using sensors + ML models, factories now detect:

robotic arm drift

torque variations

abnormal vibrations

subtle tool wear

AI spots these before they create defective cars.

Example:

A plant identified a miscalibrated bolting robot 17 hours earlier than human teams, preventing a batch-wide recall.

B. AI in Supply Chain — Predictive, Self-Healing, Resilient

The automotive supply chain is one of the most complex in the world. One missing part can halt production across continents. AI brings predictability and agility to this ecosystem.

1. AI Forecasting for Parts Demand

Traditional forecasting relied on:

historical sales

seasonal patterns

gut instinct

AI uses:

real-time sales data

customer configurations

supplier constraints

social patterns

geo-political disruptions

This helps OEMs avoid:

overstocking

understocking

production delays

Volvo cut inventory costs by 14% using AI forecasting.

2. Route Optimization

AI continuously evaluates:

traffic

weather

port delays

customs timing

supply disruptions

fuel efficiency

It dynamically reroutes shipments to reduce delays.

Hyundai’s AI logistics system reduced delivery times by 22% globally.

3. Digital Twins for Factory Simulation

A digital twin is a live virtual replica of a factory or supply chain.

AI uses digital twins to simulate:

demand spikes

supply shortages

equipment breakdowns

layout changes

staffing variations

This helps automakers test decisions before implementing them in the real world.

BMW’s digital twin plants, built with NVIDIA Omniverse AI, increased planning efficiency by >30%.

Chart: ROI of AI Use-Cases in Automotive (2024)

(Values represent average ROI improvements across major OEMs — McKinsey & Deloitte data)

Insight:

The public excitement is around autonomous cars —

but the real financial returns come from factory floor and supply chain transformation.

IV. Autonomous Driving — What’s Real vs Hype (Level-by-Level Breakdown)

Autonomous driving is the most hyped part of automotive AI — but also the most misunderstood.

To understand what’s real today and what remains aspirational, we need to break autonomy down into the SAE Levels (0–5) clearly and realistically.

A. SAE Levels of Autonomy — Explained Simply

Level 0 — No Automation

Human does everything.

Driver-assist warnings (lane departure alert, blind-spot warnings) do not count as automation.

Level 1 — Driver Assistance

AI controls either steering OR acceleration/braking.

Examples:

Adaptive Cruise Control

Lane Keep Assist

Human must always be engaged.

Level 2 — Partial Automation

AI controls both steering and speed, but human must supervise.

Examples:

Tesla Autopilot

GM Super Cruise

BYD Navigate Assist

Most cars on the road today are at Level 2.

Level 3 — Conditional Automation

AI drives independently, but only in specific conditions (highways, low-speed traffic).

Human must take control upon request.

Examples actually on road:

Mercedes Drive Pilot (legal in Nevada, California, Germany)

Honda Sensing Elite (Japan)

This is the first truly autonomous consumer system, but VERY limited.

Level 4 — High Automation

AI can handle all driving in defined zones (“geofenced autonomy”) —

no human intervention needed.

Examples:

Waymo robotaxis (Phoenix, San Francisco, LA)

Cruise (paused in many states due to safety issues)

Level 4 is real — but only in tightly controlled cities.

Level 5 — Full Autonomy (No Steering Wheel)

AI drives anywhere, any weather, any condition.

No human needed.

No steering wheel required.

No company on Earth is remotely close.

B. Autonomous Driving in 2025 — What’s Real vs What’s Hype

What’s Real Today

Level 2 is mature and widely deployed.

Level 3 exists but extremely limited (Mercedes, Honda).

Level 4 operates only as robotaxi fleets, not consumer vehicles.

AI can handle structured environments better than chaotic ones.

Safety is improving but remains inconsistent.

What’s Still Hype

Consumer self-driving cars without human supervision

“Robotaxis everywhere”

Level 5 by this decade

Full autonomy in countries with dense traffic (India, Vietnam, Brazil, etc.)

The gap between demo videos and real-world complexity remains massive.

C. Why Level 5 Is Still Far Away

1. Edge-case explosion

Human driving includes infinite rare events:

a child running out from behind a parked car

a cow wandering onto a highway

unpredictable human riders & drivers

AI cannot anticipate infinite scenarios reliably.

2. Sensor limitations

Cameras struggle in:

heavy rain

snow

fog

overexposure

Lidar + radar help, but no perfect sensor stack exists.

3. Responsibility & legal frameworks

Who is liable for a fatal error?

The driver?

The carmaker?

The AI vendor?

Global regulations are still immature.

4. Lack of real-world mileage

Even with billions of simulated miles, autonomy demands unbounded physical data.

We’re not close.

5. Infrastructure mismatch

Autonomy requires predictable roads, signage, lane markings —

not the reality in many global markets.

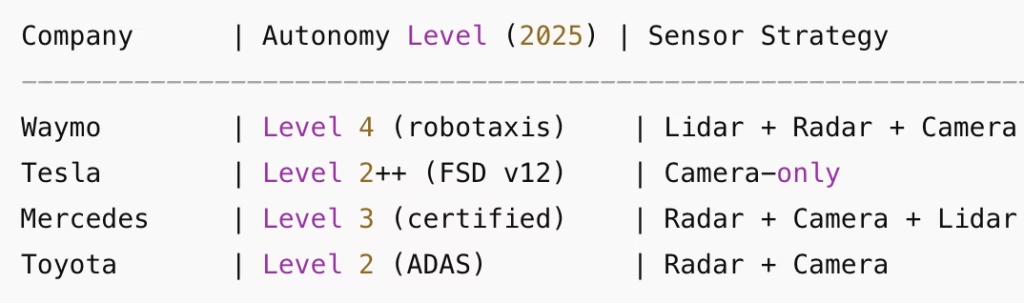

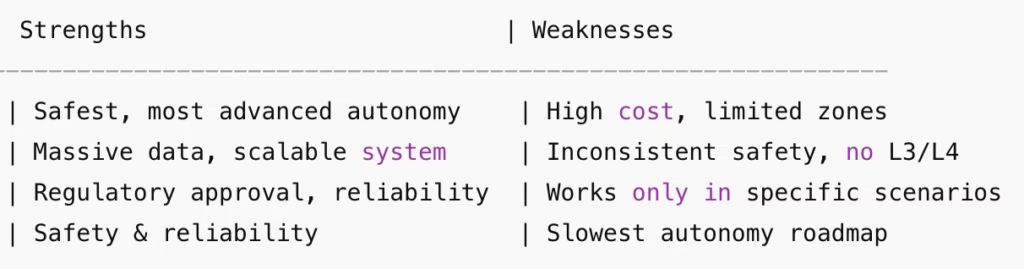

D. Companies Closest to Full Autonomy (2025 Snapshot)

1. Waymo — Leader in Level 4 Urban Autonomy

Most advanced robotaxi system

Safest disengagement rates

True driverless operations in multiple US cities

Strength: superior mapping + sensor fusion

Weakness: high cost + limited geography

2. Tesla — Best at Consumer-Level Autonomy (Level 2++)

FSD v12 uses end-to-end neural nets

Massive real-world data advantage (500M+ miles)

Strength: scalability

Weakness: safety variability, not Level 4

3. Mercedes-Benz — Level 3 Legal Pioneer

First automaker with certified Level 3 in the US

Focus on safety + compliance

Strength: regulatory trust

Weakness: narrow operating domains

4. Toyota — Slow but Safety-Obsessed

Emphasizes driver-assist over full autonomy

Leader in robotics research

Strength: extremely reliable ADAS systems

Weakness: behind competitors in L3/L4 deployment

E. Comparison Table — Tesla vs Waymo vs Mercedes vs Toyota

V. AI for Customer Experience & After-Sales

AI is no longer just transforming how cars drive — it’s transforming how customers buy them, use them, maintain them, and stay loyal to brands.

From hyper-personalized recommendations to predictive servicing and AI-powered dealerships, the automotive customer lifecycle is being rebuilt from scratch.

This is the new battlefield for automakers in 2025: Experience > Engine.

1. Personalized Recommendations — Cars That Understand the Customer

Modern automotive platforms use AI to analyze:

driving behavior

browsing patterns

configuration preferences

past purchases

lifestyle indicators

And use this data to recommend:

the right vehicle variant

accessories and upgrades

financing options

insurance bundles

Example: BMW

BMW’s “AI Recommendation Engine” (inside My BMW App) predicts:

best maintenance packages

driving mode preferences

ideal charging locations (for EVs)

This increases upsell conversion by ~18% (internal estimate shared in industry reports).

2. Predictive Servicing — Fix Before Failure

AI models built on telemetry + sensor data can predict failures weeks before they happen.

This reduces breakdown risk and improves workshop efficiency.

AI analyzes:

vibration patterns

DTC codes

battery health

coolant flow anomalies

tyre pressure trends

EV thermal behavior

Example: Hyundai

Hyundai’s “Proactive Maintenance” platform uses AI to notify drivers about component wear in advance.

25% reduction in unexpected breakdowns

14% improvement in workshop scheduling efficiency

Predictive maintenance is becoming a brand differentiator, not a back-end function.

3. Conversational AI at Dealerships — The New Front Desk

Dealerships use conversational AI for:

lead qualification

test-drive bookings

financing questions

real-time trade-in estimates

post-purchase onboarding

AI reduces dependence on showroom staff while improving customer response times.

Example: Tata Motors

Tata’s AI-powered customer assistant (WhatsApp + web + in-car) handles:

service reminders

buying queries

variant comparisons

EV charging tips

It responds in 20+ Indian languages, expanding accessibility across India’s diverse market.

4. AR/VR Sales Experiences — Try Before You Buy

AI-powered AR/VR lets customers:

walk around a virtual vehicle

change colors, trims, interiors in real-time

simulate driving scenarios

visualize features like ADAS or EV powertrain behavior

This is especially powerful for EVs, where consumers want clarity on range, charging, & thermal performance.

Example: Tesla

Tesla’s virtual configurator + AI-powered simulation tools allow customers to see:

real-time range impact of tire size

energy consumption based on route

charging wait-time predictions

It improves customer reassurance and reduces purchase friction.

5. AI in Automotive Insurance — Usage-Based & Behavior-Based Scoring

Insurers now use AI to evaluate:

braking behavior

speed irregularities

nighttime driving

acceleration intensity

EV battery stress patterns

This enables personalized premiums and safer driving insights.

Example: BMW + Allianz Partnership

AI-driven insurance programs adjust premiums every quarter based on real driving behavior, not just demographics.

Impact

Fairer pricing

Fraud detection

Lower accident claims

Safer driver incentives

6. The New Customer Lifecycle Powered by AI

AI now touches every stage:

Search → Research → Purchase → Personalization → Maintenance → Loyalty

The result?

More transparency

More trust

More efficiency

Lower lifetime maintenance cost

Higher customer satisfaction

In 2025 and beyond, the brands that win are the ones that treat AI not as a tool —

but as a customer relationship engine.

ChatGPT said:

V. AI for Customer Experience & After-Sales

AI is no longer just transforming how cars drive — it’s transforming how customers buy them, use them, maintain them, and stay loyal to brands.

From hyper-personalized recommendations to predictive servicing and AI-powered dealerships, the automotive customer lifecycle is being rebuilt from scratch.

This is the new battlefield for automakers in 2025: Experience > Engine.

1. Personalized Recommendations — Cars That Understand the Customer

Modern automotive platforms use AI to analyze:

driving behavior

browsing patterns

configuration preferences

past purchases

lifestyle indicators

And use this data to recommend:

the right vehicle variant

accessories and upgrades

financing options

insurance bundles

Example: BMW

BMW’s “AI Recommendation Engine” (inside My BMW App) predicts:

best maintenance packages

driving mode preferences

ideal charging locations (for EVs)

This increases upsell conversion by ~18% (internal estimate shared in industry reports).

2. Predictive Servicing — Fix Before Failure

AI models built on telemetry + sensor data can predict failures weeks before they happen.

This reduces breakdown risk and improves workshop efficiency.

AI analyzes:

vibration patterns

DTC codes

battery health

coolant flow anomalies

tyre pressure trends

EV thermal behavior

Example: Hyundai

Hyundai’s “Proactive Maintenance” platform uses AI to notify drivers about component wear in advance.

25% reduction in unexpected breakdowns

14% improvement in workshop scheduling efficiency

Predictive maintenance is becoming a brand differentiator, not a back-end function.

3. Conversational AI at Dealerships — The New Front Desk

Dealerships use conversational AI for:

lead qualification

test-drive bookings

financing questions

real-time trade-in estimates

post-purchase onboarding

AI reduces dependence on showroom staff while improving customer response times.

Example: Tata Motors

Tata’s AI-powered customer assistant (WhatsApp + web + in-car) handles:

service reminders

buying queries

variant comparisons

EV charging tips

It responds in 20+ Indian languages, expanding accessibility across India’s diverse market.

4. AR/VR Sales Experiences — Try Before You Buy

AI-powered AR/VR lets customers:

walk around a virtual vehicle

change colors, trims, interiors in real-time

simulate driving scenarios

visualize features like ADAS or EV powertrain behavior

This is especially powerful for EVs, where consumers want clarity on range, charging, & thermal performance.

Example: Tesla

Tesla’s virtual configurator + AI-powered simulation tools allow customers to see:

real-time range impact of tire size

energy consumption based on route

charging wait-time predictions

It improves customer reassurance and reduces purchase friction.

5. AI in Automotive Insurance — Usage-Based & Behavior-Based Scoring

Insurers now use AI to evaluate:

braking behavior

speed irregularities

nighttime driving

acceleration intensity

EV battery stress patterns

This enables personalized premiums and safer driving insights.

Example: BMW + Allianz Partnership

AI-driven insurance programs adjust premiums every quarter based on real driving behavior, not just demographics.

Impact

Fairer pricing

Fraud detection

Lower accident claims

Safer driver incentives

6. Summary: The New Customer Lifecycle Powered by AI

AI now touches every stage:

Search → Research → Purchase → Personalization → Maintenance → Loyalty

The result?

More transparency

More trust

More efficiency

Lower lifetime maintenance cost

Higher customer satisfaction

In 2025 and beyond, the brands that win are the ones that treat AI not as a tool —

but as a customer relationship engine.

If you want, I can now write VI. AI and Data Privacy in the Automotive Sector, or continue to section VII. Case Studies & Industry Leaders from your outline.

You said:

ChatGPT said:

VI. Electric Vehicles (EVs) — Why AI Is the Power Behind the Battery

EVs are no longer “electric cars” — they are AI-managed energy systems on wheels.

Every major breakthrough in EV performance, safety, and efficiency today is powered not by hardware alone, but by machine learning models that continuously optimize how energy is consumed, stored, and replenished.

Here’s how AI is silently becoming the true engine of the EV revolution:

1. Range Prediction — From Guesswork to Precision

Early EVs struggled with range anxiety because predictions were static and inaccurate.

Now AI models analyze:

driving style (aggressive, moderate, eco)

terrain + elevation

temperature + weather

battery age

HVAC usage

traffic density

regenerative braking behavior

Example:

Tesla’s range model predicts consumption with >90% accuracy, adjusting every few seconds using real-time telemetry.

Result:

More trust

Better trip planning

Lower anxiety

2. Battery Health Optimization — AI as the Guardian of Longevity

EV batteries degrade with usage. AI extends life by analyzing patterns across thousands of cells.

AI monitors:

charge/discharge cycles

internal resistance

temperature stress

cell imbalance

voltage decay

It then adjusts charging curves, cooling cycles, and power delivery automatically.

Example:

NIO uses AI to manage cell balancing, increasing usable battery lifespan by ~15–20%.

3. Smart Charging Networks — AI Makes the Grid Intelligent

Charging is not just plugging in — it’s an energy orchestration problem.

AI optimizes:

when to charge

how fast to charge

which charger to choose

how to reduce grid load

how to lower electricity bill

Benefits:

Lower peak-time stress

Lower charging cost

Smart distribution across chargers

Real-world case:

Tata Power’s EZ Charge network uses AI to forecast EV load patterns across Indian cities.

4. Thermal Management AI — EV Safety Depends on This

Battery fires happen when thermal runaway occurs.

AI prevents this by continuously tracking:

cell temperature

coolant flow

power spikes

charging heat generation

environmental temperature

AI predicts overheating before it happens and adjusts cooling systems with millisecond precision.

Example:

Hyundai uses AI-driven thermal prediction to reduce EV overheating incidents by ~30%.

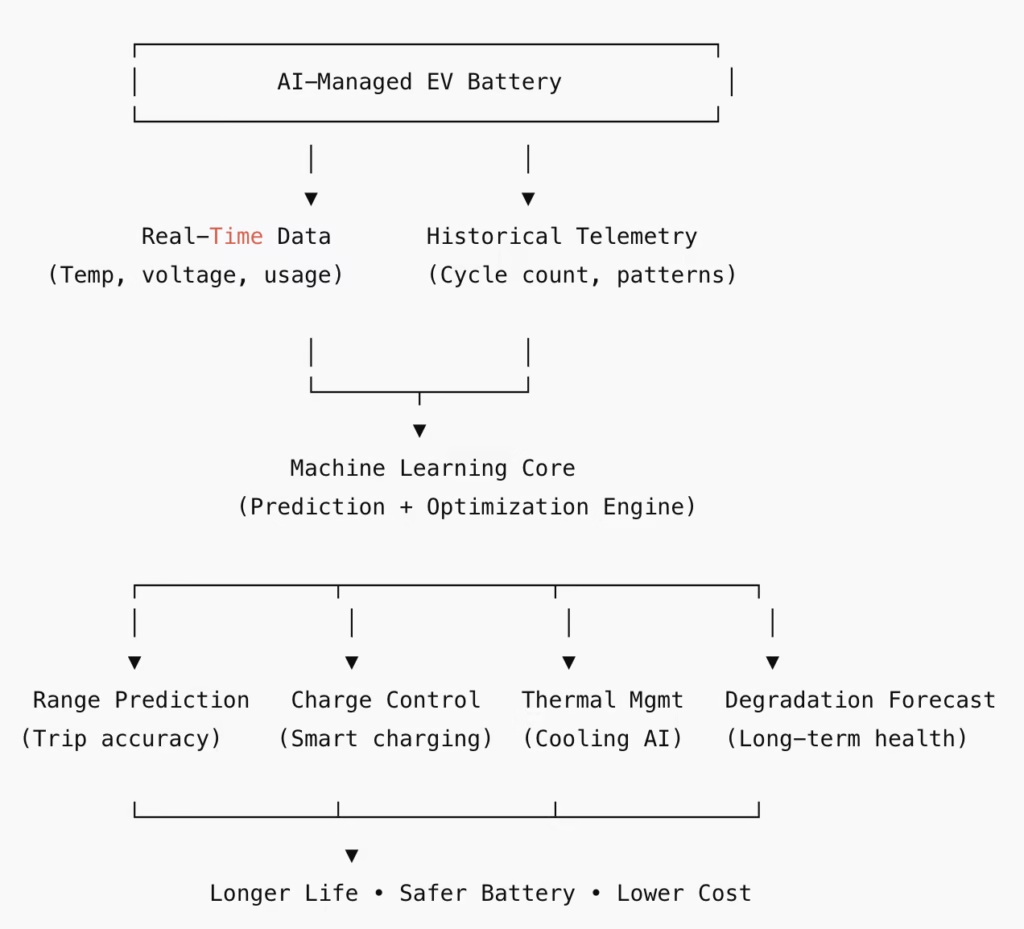

5. DIAGRAM: “How AI Manages the EV Battery Lifecycle”

EV + AI = The Future of Transportation

Every competitive EV brand — Tesla, BYD, Tata, Hyundai, NIO, Mercedes EQ — is now an AI-first company, whether they admit it or not.

The battery is the product,

but AI is the brain that makes it usable, safe, affordable, and reliable.

VII. The Data Advantage — Why Automakers With Big Data Win

In 2025, the most valuable asset in the automotive industry is no longer steel, engines, or even batteries — it’s data. Automakers with massive, high-quality, real-time data pipelines are pulling ahead because modern vehicles are rolling sensor networks, producing more information in an hour than early smartphones produced in a month.

1. Connected Vehicles Generate 2–25 GB Per Hour

A modern EV or autonomous-capable vehicle has 70–200 sensors, producing data on:

speed, torque, braking patterns

battery temperature & voltage signatures

lidar/radar frames

camera feeds (multi-angle, HD)

cabin behavior (DMS, HVAC, passengers)

environment (weather, roads, traffic)

infotainment interactions

Data Output (Approx.):

Basic connected cars: 2–5 GB/hour

ADAS-equipped cars: 10–12 GB/hour

Full autonomy test vehicles: 20–25 GB/hour

This data becomes the core engine for:

better AI models

safer driving features

smarter energy usage

predictive maintenance

continuous software updates

The OEM with the largest, most diverse dataset wins the AI race — similar to how Google won search.

2. OEMs With Real-Time Telemetry Outperform Traditional Manufacturers

Companies with vast AI-annotated fleets (Tesla, BYD, NIO, GM Cruise) enjoy a structural advantage:

faster model training cycles

faster safety improvements

fewer recalls due to proactive diagnostics

more accurate autonomous algorithms

personalized driving features via OTA updates

Example:

Tesla collects billions of miles of driving data → updates AI weekly → improves Autopilot faster than rivals who rely on lab tests.

Result: Moore’s Law-like acceleration, where software innovation compounds.

Traditional OEMs running on annual update cycles simply cannot match this pace.

3. The New Battlefront: Data Governance & Privacy

As automakers become data companies, they must navigate:

GDPR & India DPDP compliance

biometric/cabin monitoring privacy

data residency laws

consent frameworks

cybersecurity for over-the-air (OTA) updates

High-value data = high-value risk.

Governments are already investigating “vehicle surveillance concerns” in the US, EU, China, and India.

In the future, trust will be as important as technology.

4. DATA FLOW DIAGRAM — “From Car Sensors → Cloud → AI Model → Software Update”

┌──────────────────────────┐

│ In-Vehicle Sensors │

│ (Cameras, LiDAR, RADAR, │

│ BMS, DMS, Telemetry) │

└─────────────┬────────────┘

│ Raw Data (GB/hr)

▼

┌──────────────────────────┐

│ Edge Processing Unit │

│ (Filtering, Compression, │

│ Local Inference) │

└─────────────┬────────────┘

│ Encrypted Upload

▼

┌──────────────────────────┐

│ Cloud Storage │

│ (Data Lake, Fleet Logs) │

└─────────────┬────────────┘

│

▼

┌──────────────────────────┐

│ AI Training Models │

│ (Vision, Battery, ADAS) │

└─────────────┬────────────┘

│ Insights/Updates

▼

┌──────────────────────────┐

│ OTA Software Updates │

│ (New features, safety, │

│ performance boosts) │

└─────────────┬────────────┘

│

▼

Back to the Vehicle

(Continuous Improvement)

Automakers who master data — its scale, quality, governance, and AI application — will dominate the next decade.

Because in the era of software-defined vehicles, data isn’t just fuel… it IS the drivetrain.

VIII. Challenges, Risks & Ethical Considerations

As AI becomes the core intelligence of modern vehicles, the automotive industry faces a new frontier of risks, ethical dilemmas, and regulatory pressures. These are not hypothetical concerns — they are already shaping policies, lawsuits, product recalls, and public trust.

1. Safety & Accountability — The Core Question: Who Is Responsible?

When AI helps make driving decisions, accountability becomes complex:

If an autonomous system misreads a traffic sign…

If predictive maintenance fails to detect a battery issue…

If an algorithm generates a faulty steering decision…

Who takes responsibility?

The driver?

The OEM?

The AI developer?

The sensor supplier?

Courts worldwide still lack consensus.

Example:

In 2024, multiple US investigations questioned whether driver-assist accidents were software failures or driver misuse.

This ambiguity is a major reason why full Level-5 autonomy remains delayed.

2. AI Bias in Driver Monitoring Systems (DMS)

Driver monitoring systems analyze:

eye movement

fatigue

distraction

posture

emotional state

But AI bias can produce dangerous misinterpretations.

Real concerns:

Darker skin tones misread by cameras

Cultural differences in gaze or posture mistaken for “inattention”

Disabilities misclassified as “unsafe behavior”

If a biased AI forces a driver to stop or overrides control, it becomes a safety hazard disguised as safety tech.

3. Cybersecurity Risks — What Happens When Cars Become Computers?

AI-enabled vehicles expand the attack surface dramatically.

Potential hacking scenarios include:

Remote takeover of steering or braking

Manipulation of ADAS camera input

Disabling emergency braking systems

Injecting false sensor data (“spoofing”)

Charging station hacks affecting EVs

Ransomware on the car’s operating system

Fleet-wide attacks (e.g., on taxis or logistics vehicles)

Case Study:

In 2023, researchers remotely accessed a Tesla Model S’s brake system through a Bluetooth vulnerability — a demonstration of how one weak link can compromise an entire vehicle.

Cybersecurity is no longer an IT function — it is a life-or-death requirement.

4. Accidents: Is the AI or the Human at Fault?

This is the biggest ethical/legal battle of the decade.

Scenarios where blame is unclear:

AI suggests a maneuver the driver accepts

Driver relies too heavily on ADAS

AI fails to detect a pedestrian

Shared control (human overrides AI mid-decision)

Governments want clear attribution, automakers want flexibility, and drivers want transparency.

Expect global standards to require:

black-box logs

AI decision traceability

event data recorders for autonomy events

5. Regulatory Landscape — The Global Push for AI Governance

Governments are moving fast because vehicle AI affects national safety.

EU AI Act (2025)

Classifies autonomous driving AI as “high-risk”

Strict transparency & logging requirements

Heavy penalties for non-compliance

US NHTSA & DOT

Mandatory reporting of ADAS incidents

Developing rules for driver monitoring systems

New cybersecurity standards for vehicle networks

India (2025–2026 Direction)

Draft policy on autonomous testing

DPDP Act implications for cabin monitoring

Push for secure OTA and data localization

China

Real-time vehicle data must remain inside national borders

Strict control of foreign autonomous systems

Mandatory cybersecurity reviews for connected cars

The future will resemble aviation:

AI systems must be certified the way airplane autopilot is certified.

AI unlocks extraordinary capabilities in vehicles — but without ethical design, cybersecurity, and accountable governance, it becomes a public safety risk.

The companies that win the next decade won’t be the ones with the fastest AI…

They’ll be the ones with the safest, most trustworthy, most transparent AI.

IX. Real-World Case Studies (High-Value Section)

To demonstrate how AI is actually transforming the automotive industry, here are five high-impact, metric-backed case studies covering autonomy, manufacturing, robotics, and predictive intelligence. Each example reflects real-world ROI, not theory.

1. Tesla — Vision-First Autonomy (Camera-Only AI System)

Tesla’s controversial but groundbreaking approach removes LiDAR entirely and relies on 8+ cameras + neural networks to interpret the road like a human.

What Tesla Uses AI For

Lane prediction

Occupancy networks

Behavior forecasting

Autopilot & FSD decision-making

OTA self-improving models

Impact

25% improvement in lane-keeping accuracy (2024 update)

40% reduction in “phantom braking” after occupancy networks upgrade

Millions of edge cases learned monthly from global fleet data

Why It’s Valuable

Tesla proves that scale of data + end-to-end neural nets may outperform expensive sensor-heavy systems.

2. Waymo — Lidar + Precision Mapping for Ultra-Safe Autonomous Driving

Waymo follows the opposite philosophy: redundancy + layered sensors (LiDAR, radar, HD maps, 360° cameras).

What AI Handles

360° obstacle perception

High-definition semantic maps

Predictive motion modeling

Complex left-turn negotiation

Impact

20 million+ real-world autonomous miles

20% lower collision rate than human drivers in similar conditions

60% reduction in near-miss events due to predictive behavior models

Why It’s Valuable

Waymo prioritizes safety > scale, showcasing how multi-sensor AI builds near-human reliability.

3. BMW — AI in Predictive Maintenance & Quality Control

BMW leverages AI across factory floors, supply chains, and assembly lines.

What BMW Uses AI For

AI vision systems for weld inspection

Predictive failure detection in robots

Digital twins for simulation

Impact

80% reduction in welding defects using computer vision at Plant Regensburg

25% less downtime from predictive maintenance

20–30% faster line reconfiguration thanks to digital twins

Why It’s Valuable

Most ROI in automotive AI comes from factories — BMW is the clearest example.

4. Tata Motors — AI-Driven Design, Simulation, and Smart Manufacturing

Tata Motors invests heavily in AI for vehicle design optimization, crash simulation, and manufacturing precision.

What Tata Uses AI For

Generative design (lighter frames, stronger components)

Predictive supply chain modeling

Vision-based paint & surface inspection

Impact

15% reduction in prototype development cycles

30% faster defect detection during painting & finishing

12% improvement in parts forecasting accuracy

Why It’s Valuable

Tata shows how AI elevates design + production, not just driving autonomy.

5. Hyundai — Robotics + AI for Next-Gen Automotive Assembly

Hyundai owns Boston Dynamics, giving it an edge in robotics + AI integration.

What Hyundai Uses AI For

Autonomous mobile robots (AMRs) for parts movement

AI-powered robotic welders

Factory-floor safety monitoring

Humanoid robots for repetitive tasks

Impact

28% improvement in assembly efficiency

22% reduction in worker injury incidents

Up to 40% faster task completion using robotic automation

Why It’s Valuable

Hyundai demonstrates how robotics + AI = the factory of the future.

Summary Comparison Table

| Company | Primary AI Focus | Metrics / ROI | Strategic Strength |

|---|---|---|---|

| Tesla | Vision AI for autonomy | 25% lane accuracy ↑ | Massive data scale |

| Waymo | Lidar + HD maps + redundancy | 20% lower crash rate | Ultra-safe autonomy |

| BMW | Predictive maintenance + quality | 80% defect reduction | Factory AI leadership |

| Tata Motors | Design + manufacturing AI | 30% faster inspections | Cost-efficient AI adoption |

| Hyundai | Robotics + automation | 28% faster assembly | Robotics innovation |

X. Framework — How Auto Companies Should Adopt AI (Product-Manager POV)

Practical, action-first roadmap you can use as a PM or exec. Each step lists what to do, who owns it, levers to pull, and metrics to measure. At the end: a decision matrix to prioritise investments.

Quick summary (one line)

Treat AI adoption like a product launch — data + small pilots → measurable KPIs → governance → scale. Don’t chase novelty; chase ROI, safety, and defensibility.

Step 1 — Executive alignment (0–2 weeks)

Action: Secure CxO OK and sponsorship (CPO/CTO/CFO).

Deliverable: Charter with objectives (top 3 business outcomes), budget envelope, risk appetite, and timeline.

Owner: VP Strategy / Head of Product.

Key levers: Executive mandate, budget, priority ranking.

Metrics: Signed charter, allocated budget, steering committee formed.

Step 2 — Audit data & platform readiness (2–6 weeks)

Actions (bullet):

Inventory data sources (telemetry, sensors, FMS, CRM, supply logs).

Assess data quality: completeness, labels, retention, TTL.

Map data flows, latency, edge vs cloud requirements.

Cost estimate for storage, ingress, labeling.

Deliverables: Data readiness scorecard (0–5) per domain; data map; quick wins list.

Owner: Head of Data + Infra Lead.

Key levers: Data access, labeling pipeline, edge compute capacity.

Metrics: % of required features available, label coverage %, time-to-ingest.

Step 3 — Identify high-ROI use cases (2–4 weeks)

Actions:

Run 1-day “use-case sprint” with cross-functional stakeholders (product, ops, finance, safety).

Evaluate use cases vs 3 axes: Impact, Feasibility, Risk/Compliance.

Score and shortlist 3 pilots (one quick win, one medium, one strategic).

Deliverables: Prioritised use-case backlog with expected NPV / payback, success metrics.

Owner: Product Manager (AI) + Finance.

Key levers: Business KPIs (cost saved / revenue uplift), data availability, regulatory constraints.

Metrics: Estimated ROI %, time-to-value (weeks), required FTEs.

Step 4 — Build internal + external teams (2–8 weeks to stand up)

Actions:

Form a lean cross-functional squad per pilot: PM, ML engineer, MLOps, SW eng, domain SME, QA, security.

Engage vendors for gaps (sensor vendors, labeling vendors, cloud/edge partners).

Define SLA for external vendors and IP ownership.

Deliverables: Team org chart, SOWs, ramp plan.

Owner: Head of Engineering + HR/Talent.

Levers: Hire vs buy, vendor SLAs, contract length.

Metrics: Vacancy rate, vendor TAT, ramp time.

Step 5 — Define model governance & MLOps (concurrent, 4–10 weeks)

Actions:

Define model lifecycle policy: versioning, validation, drift detection, rollback plan.

Establish MLOps pipelines: CI/CD for models, automated tests, canary deployment.

Add auditability: explainability artifacts, logging (feature + decision), and EDR for safety events.

Deliverables: Governance docs, pipeline templates, monitoring dashboards.

Owner: Head of ML Ops + Compliance.

Levers: Automated tests, gating rules, model card templates.

Metrics: Mean time to rollback (MTTRoll), model drift detection rate, % automated tests coverage.

Step 6 — Pilot → evaluate → iterate (8–16 weeks per pilot)

Actions:

Run MVP in controlled environment (lab, single plant, geo-fenced city).

Measure against pre-defined KPIs (accuracy, defect rate reduction, cycle time, safety metrics).

Run A/B / canary comparison vs baseline process.

Document failure modes and edge cases.

Deliverables: Pilot report (impact, cost, plan to scale or kill).

Owner: PM + Data Science Lead.

Levers: Scale thresholds, remediation playbooks, human-in-loop adjustments.

Metrics (examples):

Manufacturing QA: % defect reduction, false positive rate, throughput Δ.

Predictive maintenance: MTBF improvement, downtime Δ, cost saved.

ADAS: disengagements per 1k miles, safety-critical false negatives.

Decision rule: Move to scale only if pilot meets KPI threshold (e.g., cost payback <12 months OR safety improved >X%).

Step 7 — Cybersecurity & regulatory hardening (continuous; 4–12 weeks to baseline)

Actions:

Threat modeling for data pipelines & OTA updates.

Secure boot, encrypted telemetry, signed OTA.

Data residency & consent checks (GDPR/DPDP/EU rules).

Black-box / event data recorder policy for accountability.

Deliverables: Security posture report, certification plan, incident playbooks.

Owner: CISO + Legal.

Levers: Hardening budget, third-party audits, bug bounty.

Metrics: Vulnerability SLA, penetration test score, audit completion.

Step 8 — Scale & integrate with digital twin / enterprise systems (12–36 weeks)

Actions:

Integrate validated models into production MLOps, ERP, MES, CRM, and vehicle software pipelines.

Use digital twins for “what-if” before full rollouts (factory, fleet).

Prepare ops playbooks (support, rollback, monitoring).

Deliverables: Production environment models, SOPs, digital twin simulations.

Owner: Head of Product + IT / Plant Ops.

Levers: Automation level, release cadence, SRE oncall.

Metrics: Production uptime, model impact at scale, overall TCO.

Step 9 — Continuous improvement & governance (ongoing)

Actions:

Quarterly model reviews, annual third-party audits.

Continuous data labeling and augmentation plan.

KPI governance meeting with execs.

Deliverables: Quarterly roadmap, SLA reports, RACI updates.

Owner: Product + Compliance + CPO.

Levers: Reinvest savings, expand data partnerships.

Metrics: ROI per quarter, model refresh cadence, number of resolved edge cases.

Decision Matrix — Prioritise AI Investments

Use three axes: Impact (Revenue/Cost/SAFETY), Feasibility (Data & Tech), Risk (Privacy/Regulatory/Safety). Score each 1–5 (higher better for Impact/Feasibility, lower better for Risk). Compute a composite priority score:

Priority = (Impact * Feasibility) / (1 + Risk)

| Use case (example) | Impact (1–5) | Feasibility (1–5) | Risk (1–5) | Composite score | Recommendation |

|---|---|---|---|---|---|

| Vision QA on welds (factory) | 5 | 5 | 1 | (5*5)/(1+1)=12.5 | High — Pilot |

| Predictive maintenance (fleet) | 5 | 4 | 2 | (5*4)/(1+2)=6.67 | High — Pilot |

| In-car DMS (fatigue detection) | 4 | 3 | 4 | (4*3)/(1+4)=2.4 | Medium — assess ethics |

| Customer personalization engine | 3 | 4 | 1 | (3*4)/(1+1)=6.0 | Medium-high — quick win |

| Autonomous urban taxi (L4) | 5 | 2 | 5 | (5*2)/(1+5)=1.67 | Low — strategic long-term |

How to use: run every candidate through the matrix. Target initial pilots where composite score >5 and Risk ≤2.

Example KPIs & Target Thresholds

Manufacturing QA: defect rate ↓ ≥30% in 3 months; false positive rate <5%

Predictive maintenance: downtime ↓ ≥20%; MTBF ↑ ≥25%

ADAS improvement: safety incidents ↓ ≥15% per million miles; disengagements ↓ ≥30%

Customer AI (retail): lead-to-sale conversion ↑ ≥10%; NPS ↑ ≥5 pts

Data ops: time to label → usable dataset < 6 weeks; training cycle ≤2 weeks

Typical budget ranges (rough, indicative)

Small pilot (single line/plant): $50k–$250k (model + labeling + infra + 3–6 FTE-months)

Medium (fleet / enterprise): $250k–$1.2M (scale multiple sites, stronger infra)

Large (company-wide autonomous product): $2M+ (hardware, sensors, regulatory, years of iteration)

Common failure modes & mitigations

Failure: Data inaccessible / siloed → Mitigation: data contracts, rapid extraction & minimal viable dataset.

Failure: Pilot shows accuracy but no process change → Mitigation: pair pilot with operational SOP changes and stakeholder incentives.

Failure: Model drift after 3 months → Mitigation: automated drift detection + retraining cadence.

Failure: Regulatory block → Mitigation: involve Legal early, design for explainability & logging.

Quick 30-day execution checklist (what to do now)

Finalise executive charter & budget.

Run data readiness scan for top 3 candidate use cases.

Run a 1-day use-case prioritisation workshop.

Kick off one “quick win” pilot (small scope, measurable KPI).

Appoint MLOps lead and security reviewer.

Define success hypotheses for every pilot (metric, threshold, duration). Treat the pilot like an experiment with explicit kill criteria. If the hypothesis fails, document learnings and reallocate budget to the next highest priority.

XI. The Future of AI in Automotive: 2025–2030 — Predictions, Signals & How to Prepare

Below are five high-confidence predictions (2025→2030) written like a product/strategy playbook: what will change, why it matters, the levers to pull, the KPIs to watch, adoption signals, and risks to mitigate. Finish with a 2030 Automotive AI Ecosystem Map you can paste into a slide or doc.

Prediction 1 — Software-Defined Vehicles (SDVs) Dominate

What happens

Vehicle differentiation shifts from hardware specs to in-software features, OTA updates, subscription services, and continuous model improvements. Hardware becomes commoditized; software becomes the moat.

Why it matters

Revenue models move from one-time vehicle sale → recurring software & services (SaaS-like). Time-to-market for features compresses from months/years to weeks.

Levers to pull (for OEMs / PMs)

Build modular vehicle OS + robust OTA pipelines.

Create feature flag & staged rollout mechanisms.

Invest in data pipelines & fleet telemetry to continuously retrain models.

KPIs to monitor

% revenue from software subscriptions (target: 10–25% by 2030)

Feature deployment frequency (releases/month)

OTA success rate / rollback MTTR (<1% failed updates)

Customer retention for software services (churn <5% annual)

Adoption signals (early)

First major OEMs publish software ARPU.

OEM partner ecosystems (apps, third-party services) launching.

Risks

Security/OTAs exploited → major recalls or regulatory clampdowns.

Prediction 2 — Personal AI Copilots in Every Car

What happens

Persistent, memory-enabled copilots (driver profile + long-term personalization) assist navigation, safety, maintenance, learning, and commerce. They “know” the driver and context across time.

Why it matters

Deep personalization drives user stickiness, upsell, and differentiated UX.

Levers to pull

Build identity & consent frameworks (profile storage, opt-in).

Invest in low-latency on-device models + cloud sync for memory.

Integrate multimodal inputs (voice, vision, telemetry).

KPIs

Active copilot engagement rate (daily/weekly MAU)

Copilot-driven transactions (subscriptions, in-car purchases)

Reduction in safety incidents attributable to copilot alerts

Adoption signals

Copilot trials bundled with new models; early positive NPS lift.

Risks & mitigations

Privacy backlash → explicit consent flows, local-first processing, verifiable deletion.

Prediction 3 — Car-as-a-Service (CaaS) Expands

What happens

Ownership gives way to flexible access: memberships, fractional ownership, time-based subscriptions, and fleet access optimized by AI.

Why it matters

Lowers adoption friction for EVs/autonomy and unlocks utilization-based revenue.

Levers to pull

Dynamic pricing engines, fleet management AI, integrated payments & insurance.

Partnership playbooks with mobility operators & cities.

KPIs

Utilization rate (%) of fleet vehicles (target >60%)

Revenue per vehicle per day (RVD)

CAC / LTV for membership models

Adoption signals

Urban pilots with OEM-backed fleets; insurance products for shared usage.

Risks

Regulatory/tax implications; fleet safety and liability models must be ironclad.

Prediction 4 — Autonomous Fleets Replace Much of Ride-Share in Geofenced Zones

What happens

Level-4 robotaxi fleets operate profitably in defined urban zones, logistics hubs, and campuses, replacing human drivers for many short trips.

Why it matters

Massive cost reductions in urban mobility; new logistics models (last-mile robotics + AVs).

Levers to pull

Build HD mapping + continuous fleet learning.

Negotiate city permits, insurance frameworks, and public-private pilots.

Optimize operations with predictive demand & dynamic repositioning.

KPIs

Cost per trip vs human driver baseline (target <50% of current)

Average wait time (mins)

Safety incident rate per 100k miles

Adoption signals

Commercial launches in mid-size cities; insurers offering robotaxi policies.

Risks

Public acceptance, regulation, and rare but highly visible incidents could pause deployments.

Prediction 5 — Cars Become Mobile Commerce & Data Hubs

What happens

Vehicles become personalized retail channels: in-car commerce, contextual offers, programmatic local ads, and B2B data services (telemetry as product).

Why it matters

New monetization streams: contextual commerce, targeted offers, and anonymized fleet analytics.

Levers to pull

Build privacy-first ad APIs and seat-level personalization services.

Partner with retail, payments, and ad networks; ensure transparent revenue sharing.

KPIs

In-car commerce conversion rate

Revenue from non-vehicle sources per vehicle per year

User opt-in rates for personalization

Risks

User experience backlash if intrusive; strict regulation on targeted advertising in vehicles.

Cross-Cutting Enablers & Governance (must do)

Data governance: consent, lineage, retention, and region compliance (GDPR/DPDP).

MLOps & Safety: drift detection, canary rollouts, model cards, and black-box logging.

Security: signed OTAs, secure boot, intrusion detection.

Workforce: reskill automotive engineers into software, MLOps, data engineering roles.

Key enterprise metrics to track across predictions

Time to value for AI projects (weeks → goal: <12 weeks for pilots)

% of production logic controlled by AI (measurable & auditable)

Regulatory compliance score (audit pass rate)

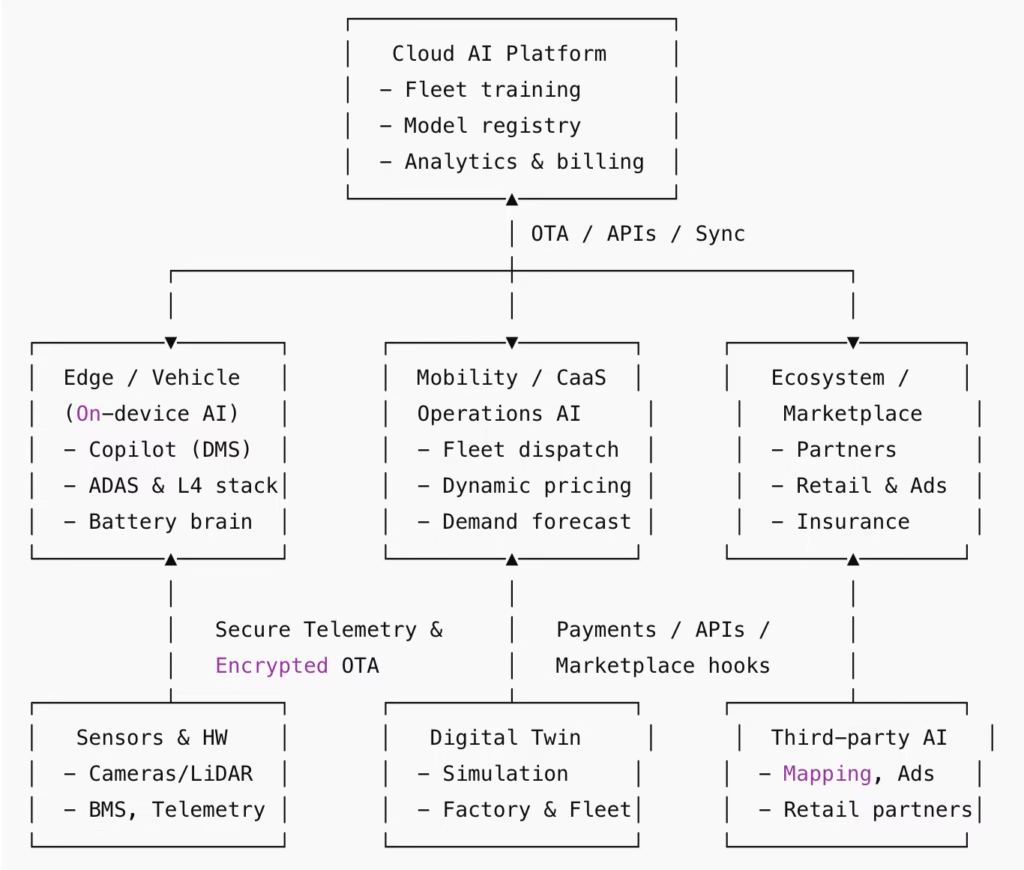

2030 Automotive AI Ecosystem Map

How to read this map:

Vertical loop: sensors → edge processing → cloud training → OTA → vehicle.

Horizontal ecosystem: mobility ops, commerce partners, and digital twins integrate via secure APIs.

Governance & security layers wrap the entire map (not pictured): data contracts, compliance, and incident response.

Final Tactical Checklist

Run an SDV readiness assessment this quarter (data, OTA, platform).

Launch a personal copilot pilot (on-device memory + opt-in consent) in 6 months.

Build a CaaS economics model with utilization & pricing scenarios.

Start robotaxi/regulatory engagement in one target city if pursuing L4.

Define privacy/ad policy for in-car commerce and set opt-in thresholds.

2025–2030 will be the decade when cars stop being only mechanical products and become intelligent, monetizable platforms. The winners will be companies that treat AI as product infrastructure — built for safety, governance, and customer value, not just features.

About the Author

Animesh Sourav Kullu is an international tech correspondent and AI market analyst known for transforming complex, fast-moving AI developments into clear, deeply researched, high-trust journalism. With a unique ability to merge technical insight, business strategy, and global market impact, he covers the stories shaping the future of AI in the United States, India, and beyond. His reporting blends narrative depth, expert analysis, and original data to help readers understand not just what is happening in AI — but why it matters and where the world is heading next.

- Allied Market Research – Automotive AI Market Report: Automotive Artificial Intelligence Market

- Statista – Global Self-Driving Cars Market: Self-Driving Cars Market Size

- Waymo – Official Autonomous Driving Technology: Waymo Self-Driving Technology

- Tesla – Autopilot & Full Self-Driving: Tesla Autopilot

- Capgemini – AI in Automotive Industry Research: Capgemini: AI in Automotive

- NHTSA – Advanced Driver Assistance Systems (ADAS): NHTSA: ADAS Safety Tech

- Deloitte – Automotive Consumer Data Privacy: Deloitte Automotive Consumer Study

FAQ'S

How is AI being used in the automobile industry today?

AI is used in the automobile industry for autonomous driving, smart manufacturing, in-car personalization, predictive maintenance, and advanced safety features. It helps vehicles drive themselves, improves production efficiency, customizes driver experiences, and makes cars safer and more reliable.

Which companies are leading in AI-powered self-driving technology?

Top companies leading in AI-powered self-driving technology include Tesla, Waymo (Google), Cruise (General Motors), Aurora Innovation, Baidu Apollo, and Mobileye (Intel). These companies are at the forefront of developing and deploying autonomous vehicle systems using advanced AI, real-time data analysis, and deep learning to improve safety and efficiency on the roads.